Workplace Health and Safety Webinar

Fume Extraction and the Benefits to your Workforce

Thursday, March 28th from 1:00PM to 2:00PM EST

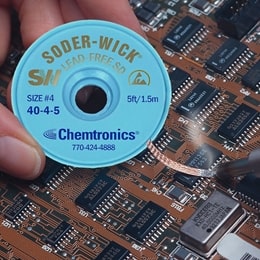

CE3S and PACE discuss how addressing airborne hazards in your workplace is key to boosting productivity and protecting employee health. Join our free webinar to gain insights into managing fume risks in PCB Assembly and Rework. Our team will share effective strategies to ensure your team’s safety and enhance operational efficiency.